Release base paper is a significant component of the industry and packaging. Moreover, this type of paper is commonly used in the production of adhesive tapes, labels, laminates, and protective films that require a specific amount of paper release. When selecting a supplier for a company that uses pressure-sensitive adhesive that needs silicone release paper, efficiency, costs, and product quality are directly affected. In this regard, selecting the right supplier is important.

What Is Release Base Paper?

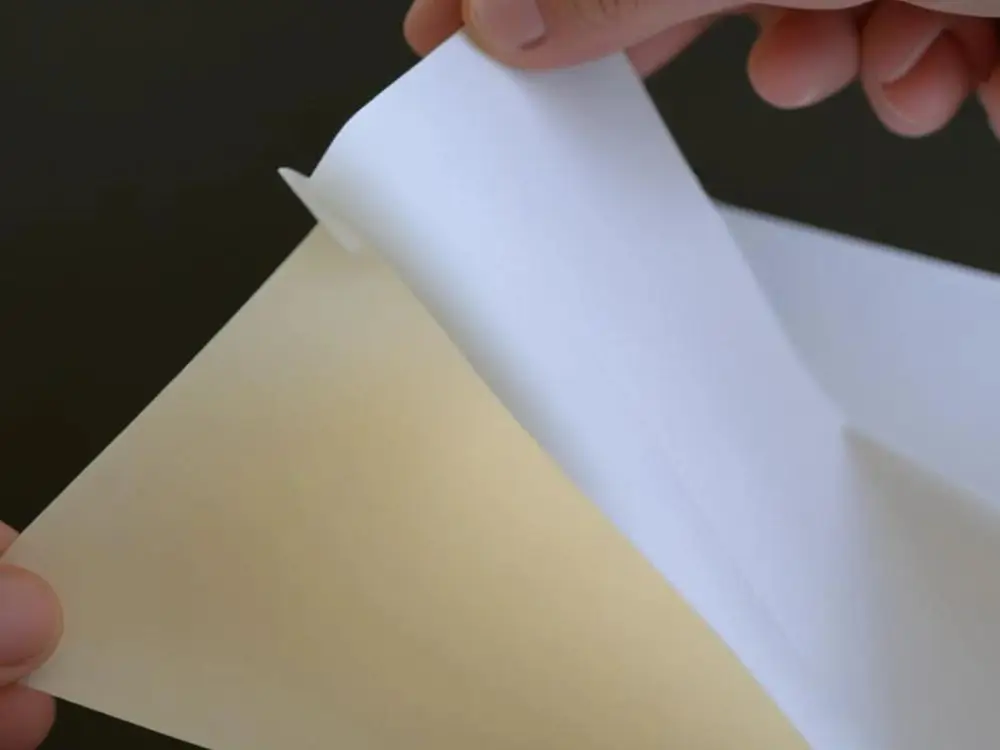

Base paper for release is engineered paper with a controlled release surface and is usually surfaced with a silicone or equivalent to prevent it from sticking when an adhesive is applied to it.

Essential Features of Release Base Paper

- Made from high-quality base paper materials glassine, or kraft

- Treated with a silicone coating for easy release

- Provides smoothness, dimensional stability, and thickness equalization

A good quality release base paper supplier will ensure the paper works well in any given industrial use.

What Makes Release Base Paper Unique

Release base papers differ from common ones by their special coating and performance features. In fact, this aspect is critical to industries that deal in adhesives and laminates.

Advanced Coating Technology

Silicone coatings are done using well-controlled techniques for a proper pattern of coverage. This allows controlled release of adhesives without any residues. A good silicone release paper supplier keeps the standard of coating to the highest level.

Also Read –

Controlled Release Force

Release force determines the ease with which adhesive materials separate from paper. Accurate control prevents tearing or transfer of adhesives. This property is very important for labels and industrial tapes.

High Stability and Smooth Surface

Release base paper retains shape under heat and pressure. Its smooth surface promotes good adhesive performance and product uniformity in application.

Common Uses of Release Base Paper

Variously, the release base paper is applied to several industries because of its versatility and reliability.

Major Applications

Adhesive tapes

Applied as release liners for pressure-sensitive tapes, it allows easy unwind without adhesive loss.

Silicone Coated Release Liners

Used in such applications as medical tapes, hygiene products, and specialty adhesives. A silicone release paper supplier ensures clean and consistent release.

Production Label

Used as a liner in the manufacture of self-adhesive labels for packaging, logistics, and retail.

Protective Films

Used for the protection of surfaces during transport and installation. Release base paper prevents contamination and damage.

Types & Grades of Release Base Paper

Different applications require different grades of release base paper. A professional release base paper supplier offers multiple grades to meet diverse needs.

| Grade | Typical Use | Key Feature |

| Glassine | Pressure-sensitive tapes | High transparency |

| Silicone Release | Labels & liners | Controlled release |

| Kraft Release | Industrial tapes | Strength & durability |

Each grade offers specific benefits depending on adhesive type, application environment, and performance requirements.

How to Choose a Good Release Base Paper Supplier

Step 1: Assess Product Quality & Consistency

A good quality release base paper supplier should provide quality in every production lot delivered. It is essential to check the paper for smoothness and uniform coating and release force values. Supplier Selection Criteria A release base paper supplier should be judged on the following criteria.

Step 2: Research Technical Skills and Competencies

Select a supplier knowledgeable in release force, coating methods, and applications. Good technical services enable you to solve problems quickly, thereby guaranteeing that your paper functions effectively in your operation.

Step 3: Examine the Capabilities

A good supplier should offer customized coatings, gsms, and levels depending on your requirements. Customized solutions are critical in productions such as labels, laminates, and industry tapes, where precision is a priority.

Step 4: Verify Certifications and Compliance

The supplier of the Release Base Paper should ensure that the international quality standards are met, along with proper TDS and SDS documents. It ensures that the product is safe, reliable, and exportable for manufacturing.

Step 5: Evaluate Delivery Speed and Supply Chain Reliability

On-time delivery is essential to prevent delays in the product development process. An efficient supplier has good logistics and inventory management to ensure a continued flow of supplies, even when dealing with large quantities.

Step 6: Compare Pricing and Long-Term Value

Although being competitive in terms of pricing is key, one should prioritize long-term value for money as opposed to seeking the lowest prices. This is because the supplier with reliable pricing, quality, and technical support will always be more profitable in the long run.

Questions to Ask Your Release Base Paper Supplier

What surface finishes do you offer?

Before closing a deal with the supplier, these are the kinds of questions that should be asked.

What types of surface finishes do you offer?

The required levels of smoothness or coating vary with applications.

Do you have documentation for SDS and TDS?

Technical Data Sheets and Safety Data Sheets ensure compliance.

Can the release force be customized?

The release force for the custom version must vary. These questions assist in determining a technically skilled release base paper supplier.

FAQs for Release Base Paper

What is release force?

Release force refers to the effort required to separate adhesive material from the release paper. Proper control ensures easy removal without damage.

How is the Release Base Paper rated?

The grading of paper is based on the base paper quality, thickness of coatings, release force, and end application. Glassine paper, silicone paper, and kraft paper are the main types of paper

Can releasing base paper be recycled?

Some grades are recyclable, depending on the type of coating. There are now many suppliers who concentrate on “green” and sustainable release papers.

The benefits of working with the right release base paper supplier:

Ensures Product Performance

Consistent release properties enhance the final product quality since it reduces reworks and material waste.

Improves Production Efficiency

High-quality release base paper cuts down on machine downtime. Smooth processing saves time and costs.

Meets customized industrial requirements.

Different industries have different needs when it comes to the release behavior of papers. An capable silicone release paper supplier adapts itself to unique requirements.

Reduces Long-Term Costs

Reliable materials minimize defects and rejected batches. This improves overall profitability.

Boosts Brand Reliability

Final products are also superior in their qualities, which helps in increasing customer satisfaction and garnering trust.

Supports Scalable Growth

A reliable supplier supports higher volumes when business demand increases.

Step-by-Step: Release Base Paper Supply Process

Step 1: Selection of Raw Paper

Top-quality base paper is used for strength and smoothness.

Step 2: Application of the Coat

It is coated with an equal layer of silicone for controlled release force.

Step 3: Testing and Quality Control

Release strength, thickness, and surface quality are evaluated.

Step 4: Slitting & Packaging

The paper is then cut to the desired sizes and packed carefully.

Step 5: Logistics / Delivery

The orders are dispatched safely and properly documented.

Conclusion

Selecting an appropriate supplier for the release base paper is crucial for industries that require accuracy, uniformity, and excellence. For adhesive tapes, labels, laminates, and protective films, high-quality release paper has a significant effect on commercial successes. At Skpmil, a reputable supplier of high-quality silicone release paper provides assured quality, customization, and timely delivery of goods as per international standards for all kind of businesses requiring trustworthy release base paper suppliers.