Choosing the right release paper is one of the most important decisions for manufacturers, packaging specialists, and product developers who work with adhesives, laminates, or specialty coatings. The correct release paper can save you time, reduce production costs, improve product quality, and ensure smooth workflow. In this guide, we provide practical advice, expert tips, and industry insights to help you select the best release paper for your needs.

What is Release Paper and Why It Matters

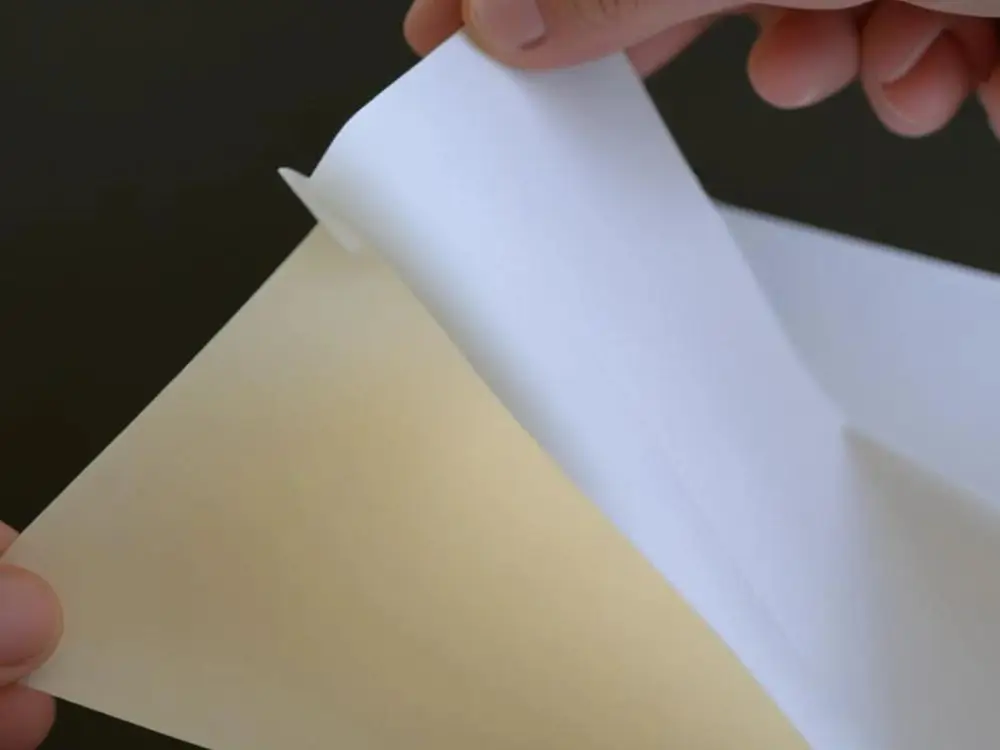

Release paper, also known as release liner or silicone-coated paper, is a specially treated paper designed to prevent sticky materials like adhesives from adhering permanently. It acts as a protective barrier, ensuring that your adhesive products, labels, stickers, tapes, and laminates can be easily applied without sticking to unintended surfaces.

Key Uses of Release Paper:

- Adhesive tapes and labels: Ensures clean peel-off without residue.

- Laminated products: Protects surfaces during heat or pressure processes.

- Medical applications: Used in bandages, transdermal patches, and medical tapes.

- Industrial applications: Supports adhesive films, rubber sheets, and thermal transfers.

- Food packaging: Prevents food items from sticking to packaging materials.

Without the right release paper, products may stick improperly, causing waste, production delays, and compromised quality.

Types of Release Paper

Choosing the correct type of release paper depends on your adhesive type, production method, and application requirements. Here are the most common options:

1. Glassine Release Paper

Glassine is smooth, translucent, and glossy. It is ideal for high-quality adhesives and delicate surfaces, such as labels, stickers, and decals.

Advantages:

- Smooth surface for delicate adhesives

- Excellent transparency for visibility

- High-quality appearance for premium products

Limitations:

- Higher cost compared to kraft

- Limited thickness options

2. Kraft Release Paper

Kraft paper is durable and made from natural wood pulp, making it ideal for industrial and heavy-duty applications.

Advantages:

- Strong and tear-resistant

- Affordable and widely available

- Available in various thicknesses

Limitations:

- Slightly rough surface, less suitable for delicate adhesives

- Not ideal for premium appearance products

3. Coated and Specialty Release Papers

Specialty release papers are silicone-coated or chemically treated for specific applications, such as medical tapes, heat-resistant films, or UV-curable adhesives. These papers offer precise release control and withstand extreme conditions.

Advantages:

- High-temperature tolerance

- Superior release properties

- Customized coatings for specific adhesives

Limitations:

- Higher cost

- Requires testing for each unique application

Key Factors to Consider When Selecting Release Paper

Selecting the right release paper involves evaluating multiple factors. Here are the most critical ones:

1. Adhesive Compatibility

The type of adhesive directly impacts which release paper works best. Common adhesives include:

- Rubber-based: Works well with kraft or lightly coated papers.

- Acrylic-based: Requires smooth, silicone-coated surfaces.

- Hot-melt adhesives: May need high-temperature resistant papers.

Testing your adhesive with the paper ensures clean release and no residue.

2. Release Coating Quality

The release coating, usually silicone-based, determines how easily your adhesive separates from the paper. High-quality coatings ensure:

- Consistent release strength

- Minimal adhesive residue

- Long shelf life

3. Paper Thickness and Strength

GSM (grams per square meter) affects durability and flexibility. Thinner papers may tear in high-speed machinery, while thicker papers are more stable but costlier. Choose thickness based on:

- Production speed

- Type of adhesive

- Application environment

4. Surface Smoothness

The smoothness of the paper affects the adhesive’s behavior. Glassine paper is ideal for delicate adhesives requiring perfect release, while kraft works for heavy-duty adhesives.

5. Temperature and Environmental Resistance

Some processes involve high temperatures or humidity, such as:

- Heat transfer printing

- Hot laminations

- UV curing

Choose release papers that maintain integrity under heat and moisture. Specialty silicone coatings can handle up to 220°C in certain industrial processes.

6. Environmental Impact

Eco-conscious businesses should consider:

- Recyclable kraft or glassine papers

- Biodegradable coatings

- FSC-certified papers

Sustainable options reduce environmental impact while maintaining performance.

Practical Tips for Selecting the Right Release Paper

Choosing release paper can be overwhelming, but these tips can help you make informed decisions:

Identify Your Product Requirements

Determine your application type, adhesive type, production conditions, and desired release characteristics. For example:

- Stickers – Glassine release paper

- Industrial tapes – Kraft release paper

- Medical patches – Specialty silicone-coated release paper

Test Before Committing

Request sample rolls and conduct tests under real production conditions. Look for:

- Clean release without residue

- Consistency under pressure or heat

- No tearing or deformation

Partner with a Trusted Release Base Paper Supplier

A reliable supplier, such as SKPMIL, provides:

- Technical guidance and recommendations

- Consistent quality

- Customization options (coating type, thickness, size)

Choosing a trusted supplier ensures that you receive high-quality release papers that perform consistently, helping you avoid production delays and waste.

Balance Cost and Quality

Cheaper papers may seem cost-effective, but they often lead to:

- Production delays

- Material waste

- Compromised product quality

Invest in quality papers from a reputable supplier like SKPMIL that deliver reliable performance, even if upfront costs are slightly higher.

Check Regulatory Compliance

For food, medical, or adhesive products, make sure your release paper complies with:

- FDA or CE standards

- ISO certifications

- Industry-specific requirements

Compliance ensures safety and avoids legal or operational issues.

Benefits of Using the Right Release Paper

Using the correct release paper has several advantages:

- Smooth production workflow: Minimizes stoppages and errors.

- High-quality final product: Clean release ensures premium appearance.

- Reduced waste and cost: Less material wasted and fewer defects.

- Regulatory compliance: Safe for food, medical, or sensitive applications.

- Environmental sustainability: Eco-friendly options reduce environmental impact.

- Reliable sourcing: Partnering with a trusted supplier like SKPMIL guarantees consistency and technical support.

Ready to Purchase Release Paper?

If you’re looking for a trusted release base paper supplier, SKPMIL offers a wide range of high-quality release papers tailored for industrial, medical, and packaging applications.

Why choose SKPMIL?

- Wide variety of glassine, kraft, and coated release papers

- Expert technical support for selecting the right paper

- Consistent quality and customizable options

- Competitive pricing for bulk orders

Take the next step: Contact SKPMIL today and get the perfect release paper solution for your production needs.